When you bite into a chewy gummy candy, swallow a smooth pharmaceutical capsule, or enjoy a silky pudding, have you ever wondered where that elastic and transparent substance comes from? This common "gelling agent" in everyday foods and medicines—gelatin—often has origins that surprise people. Is gelatin made from bones? The answer is yes—but it's far more than that. This article delves into the truth about Bone Gelatin, exploring its sources, production process, and diverse applications in detail.

What Is Bone Gelatin?

Bone Gelatin is a specific type of gelatin extracted primarily from animal bones (such as bovine/cow, porcine/pig, or sometimes chicken bones), rather than skins or other tissues. It is a pure, natural protein obtained through the partial hydrolysis of collagen—the main structural protein found in bones and connective tissues.

Unlike general gelatin (which can come from skins, hides, or a mix), Bone Gelatin often has higher gel strength (measured in Bloom values, typically 200-300g), making it firmer and more suitable for certain applications.

Sources of Gelatin: Bones Are the Star, But Not the Only One

Gelatin is essentially the product of hydrolyzed collagen from animal connective tissues. Collagen is a structural protein widely found in animal skin, bones, cartilage, and tendons. So, what exactly are the raw materials for how is gelatin made?

Animal bones (primary source for Bone Gelatin): Bovine bones, porcine bones, and chicken bones account for over 80% of global gelatin raw materials. In particular, bovine and porcine bones have high collagen content (about 30-40% of dry weight) and long molecular chains (mainly Type I collagen), offering high gel strength (Bloom values up to 200-300g), making them ideal for industrial production.

Animal skins: Porcine and bovine hides are traditional sources, often used for high-end gelatin, such as in photography or pharmaceutical grades.

Fish sources: Fish bones and skins produce fish gelatin, suitable for Halal and Kosher certifications.

Why are bones so popular?

First, bones are by-products from slaughterhouses, offering high utilization, low cost, and sustainability.

Second, the collagen in bones is structurally stable, yielding superior performance after extraction.

Importantly, these materials come from food processing by-products, not animals slaughtered specifically for gelatin—promoting resource efficiency and waste reduction.

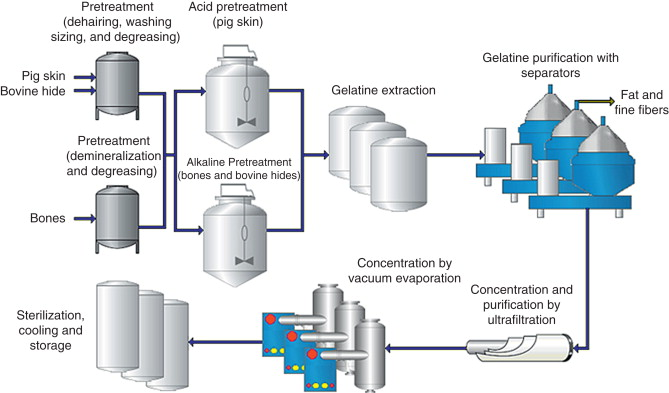

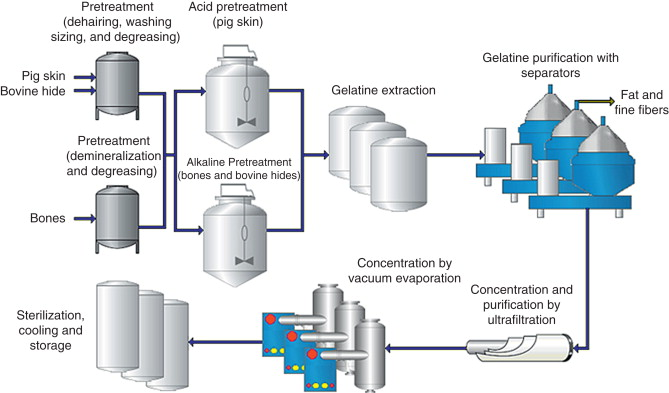

How Bone Gelatin Is Made from Animal Bones

The process of gelatin made from bones is highly industrialized, involving physical, chemical, and biotechnological steps. Modern factories use closed-loop systems for hygiene and environmental protection. Here's a typical flowchart for Bone Gelatin production:

Step | Description | Key Technologies | Purpose |

1. Pre-treatment | Cleaning bones to remove residual meat, fat, and impurities; crushing into 2-10cm pieces | Mechanical cleaning, high-pressure rinsing, crushers | Increase surface area for better extraction efficiency |

2. Demineralization & Extraction | Acid process (HCl soaking for demineralization) or alkaline process (lime treatment); enzymatic assistance | Acid/alkaline soaking for weeks, enzymatic hydrolysis | Release collagen, break down non-collagen components |

3. Hot Extraction & Filtration | Hot water extraction of collagen solution; multi-stage filtration to remove residues | Cooking tanks, centrifugal filtration, microfiltration | Obtain pure collagen solution |

4. Concentration & Purification | Vacuum evaporation to 30-50% concentration; ion exchange for impurity removal | Evaporators, ultrafiltration | Enhance concentration and purity |

5. Gelation & Drying | Cooling to form gel; roller or spray drying | Dryers, milling | Produce sheet, powder, or granular gelatin |

Common Misconceptions and Scientific Facts

Many myths surround Bone Gelatin—let's clarify with facts:

Misconception: Gelatin is vegetarian

Truth: Traditional gelatin is 100% animal-derived and not suitable for strict vegetarians. However, plant-based alternatives (like agar or pectin) are rising.

Misconception: Eating gelatin is like eating bones directly

Truth: Gelatin consists of small peptide chains from hydrolyzed collagen, easily absorbed and providing amino acids (like glycine and proline) for joint and skin health—but its nutrition differs entirely from raw bones.

Misconception: Gelatin production is highly polluting

Truth: Modern factories use water recycling and residue conversion, reducing wastewater by over 90%; bone residues become fertilizer or biofuel.

Bone Gelatin vs Skin Gelatin: What’s the Difference?

While both Bone Gelatin and skin-derived gelatin come from animal collagen, they differ significantly in source, processing, properties, and applications. Skin gelatin (primarily from porcine or bovine hides) is the most common globally, but Bone Gelatin plays a key role in specific industries due to its unique characteristics.

Aspect | Bone Gelatin | Skin Gelatin (Porcine/Bovine Hides) |

Primary Source | Animal bones (mainly bovine or porcine ossein) | Animal skins/hides |

Processing | Requires demineralization (acid/alkaline to remove minerals), longer extraction | Direct acid or alkaline pretreatment, shorter process |

Gel Strength (Bloom Value) | Typically higher (200-300 Bloom); firmer gels due to longer collagen chains | Varies; often medium-high (150-275 Bloom); porcine skin can reach high Bloom |

Viscosity | Generally lower | Higher, especially Type A from porcine skin |

Color & Odor | Lighter color, more neutral odor | Can be slightly darker or have mild odor |

Applications | Preferred for high-strength needs like hard capsules, gummies requiring firm texture; common in pharmaceutical grades | Widely used in food (gummies, marshmallows), photography, and cosmetics for clarity and elasticity |

Yield & Cost | Lower yield per raw material weight; often more cost-effective as bone is a by-product | Higher yield; dominant in global production (pig skin ~50% of market) |

Diverse Applications of Gelatin: From Everyday Food to Cutting-Edge Tech

While general gelatin applications span multiple sources, Bone Gelatin excels in areas requiring firmness, purity, and stability—making it a preferred choice in pharmaceuticals, certain foods, and advanced biomedical fields. Globally, gelatin production stands at around 441,000-500,000 tons annually (based on 2024-2026 industry estimates from sources like ChemAnalyst and Mordor Intelligence), with food and pharma driving demand.

Below, we explore its key applications, emphasizing where Bone Gelatin shines due to its superior mechanical strength and neutral profile.

1. Food Industry: Texture and Stability in Everyday Treats

Bone Gelatin is widely used in food for its high gel strength, providing firm textures ideal for products that need durability.

Confectionery: Essential for chewy gummies, marshmallows, and jellies—Bone Gelatin ensures a strong "snap" and heat resistance.

Dairy and Beverages: Stabilizes yogurt and acts as a clarifier in wines/beers.

Meat Products: Enhances elasticity in processed meats; also used as a low-fat alternative.

Its cost-effectiveness from by-products makes it a staple in large-scale food manufacturing.

2. Pharmaceutical and Medical: Precision and Biocompatibility

This is where Bone Gelatin truly dominates, prized for its purity and high Bloom value in regulated applications.

Capsules: Over 90% of hard capsules use gelatin; Bone Gelatin is favored for its strong, brittle shells that protect sensitive drugs.

Hemostatic Agents: Absorbable sponges (e.g., Gelfoam) for surgical bleeding control—rapidly absorbs blood and promotes clotting.

Drug Delivery: Tablets, microencapsulation, and wound dressings.

Its FDA-approved status and low immunogenicity make it indispensable.

3. Cosmetics and Personal Care: Natural Enhancement

Bone Gelatin and its hydrolyzed forms provide thickening and moisturizing benefits.

Growing demand for natural ingredients drives its use in clean beauty.

4. Traditional Applications: Photography and More

Historically, high-purity gelatin (including bone-derived) was key in analog photography.

Photographic Film: Acts as a binder for light-sensitive silver halides.

Though niche today, it remains in artistic and specialty films.

5. Cutting-Edge Tech: Biomaterials and Bioprinting

Bone Gelatin is evolving into advanced applications, often modified (e.g., into GelMA—gelatin methacryloyl) for enhanced properties.

3D Bioprinting: GelMA from gelatin serves as bioink for printing bone, cartilage, skin, and vascular structures—mimicking extracellular matrix for cell growth.

Tissue Engineering: Scaffolds for bone regeneration, combining with ceramics for orthopedic implants.

Regenerative Medicine: Drug-loaded hydrogels and nanoparticles for targeted therapies.

Research highlights its role in organ printing and personalized medicine, with ongoing advancements in biocompatibility.

Bone Gelatin—A Perfect Blend of Sustainability and Innovation

Yes, gelatin made from bones is a fact, with Bone Gelatin dominating. But through precise industrial transformation, these by-products become indispensable in modern life. It utilizes resources efficiently while advancing food, medicine, and biotech. The future, with sustainable tech and alternatives, will enrich gelatin's story—but bones remain its classic origin.

Frequently Asked Questions About Bone Gelatin

1. Is bone gelatin safe to consume?

Yes. Bone gelatin produced by reputable manufacturers is considered safe and is classified as GRAS (Generally Recognized as Safe) by the FDA and equivalent authorities worldwide. High-temperature processing, filtration, and sterilization eliminate pathogens, while strict quality controls ensure compliance with food and pharmaceutical standards.

2. What bones is bone gelatin made from?

Bone gelatin is primarily extracted from bovine (cow) and porcine (pig) bones, with smaller amounts produced from chicken bones. Fish bones and skins are used for marine gelatin. These materials are by-products of the meat industry, not animals raised specifically for gelatin production.

3. Is bone gelatin halal or kosher?

It depends on the source and certification. Gelatin derived from pork bones is neither halal nor kosher. Bovine bone gelatin can be halal or kosher if the animals are slaughtered according to religious requirements and certified by recognized authorities. Fish-derived gelatin is widely accepted as both halal and kosher.

4. Does bone gelatin contain pork?

Some commercial bone gelatin is derived from porcine (pig) bones. However, many products are made exclusively from bovine or fish sources and are pork-free. Always check product labels or certifications if avoiding pork is important.

5. Does bone gelatin contain heavy metals?

High-quality bone gelatin is routinely tested for heavy metals such as lead, mercury, cadmium, and arsenic. Levels in certified food- and pharmaceutical-grade products are typically negligible and well below regulatory limits due to strict sourcing and advanced purification processes.

6. Bone gelatin vs collagen peptides: what’s the difference?

Bone gelatin is partially hydrolyzed collagen that dissolves in hot liquids and forms a gel when cooled. Collagen peptides are further hydrolyzed, dissolve easily in cold liquids, and do not gel. Both provide similar amino acids but serve different functional and formulation needs.

7. Is bone gelatin good for joints, skin, hair, and nails?

Bone gelatin contains collagen-forming amino acids such as glycine and proline. Studies suggest regular consumption may support joint comfort and help maintain skin elasticity, hair strength, and nail health as part of a balanced diet. Results vary by individual and consistency of intake.

8. What is the recommended daily dosage of bone gelatin?

Common recommendations range from 10–15 grams per day, depending on dietary needs and intended use. Some people start with smaller amounts and adjust gradually. Always follow product instructions or professional dietary guidance.

9. Bone gelatin vs bone broth: what’s the difference?

Bone gelatin is a purified protein extracted from collagen, while bone broth is a liquid food made by simmering bones with water. Gelatin offers concentrated protein and functional properties, whereas bone broth contains minerals, fats, and flavor compounds.

10. Is bone gelatin sustainable?

Yes. Bone gelatin is produced by upcycling animal bones that are by-products of the food industry. This reduces waste, improves resource efficiency, and supports circular economy practices. Modern production methods also emphasize water recycling and energy efficiency.