In the global pharmaceutical and nutritional industries, the biological safety of animal-derived excipients is paramount. This article examines the rigorous control measures required to mitigate Transmissible Spongiform Encephalopathies (TSE) risks, specifically Bovine Spongiform Encephalopathy (BSE), in the production of bone gelatin. We analyze the critical control points (CCPs) employed by leading manufacturers, such as Shandong Hengxin Biotech Co., Ltd., ranging from raw material provenance to hydrothermal processing parameters, demonstrating how strict adherence to international protocols ensures product integrity and consumer safety.

Bone gelatin is a critical hydrocolloid used extensively in soft capsules, tableting, and functional foods. However, its bovine origin necessitates stringent scrutiny regarding prion diseases. According to the World Organisation for Animal Health (WOAH, formerly OIE), ensuring a negligible BSE risk status is not merely a regulatory formality but a fundamental obligation for supply chain stability. For industrial stakeholders, selecting a manufacturer that exceeds baseline compliance is essential for mitigating liability.

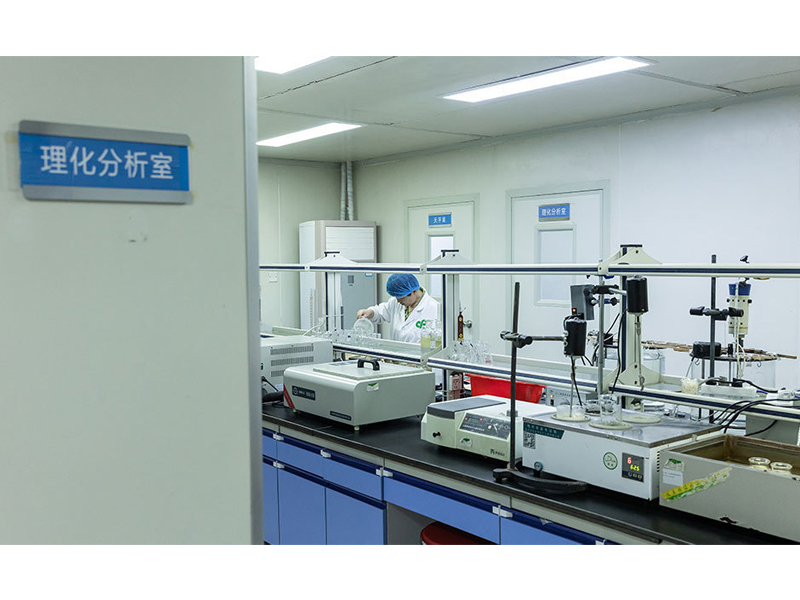

The integrity of the final gelatin product is determined prior to the extraction process.

Geographical Sourcing: Scientifically rigorous sourcing mandates that bovine bones are procured exclusively from regions classified as "Negligible Risk" regarding BSE.

Veterinary Inspection: As implemented in the protocols of Hengxin Biotech, raw materials must originate from animals deemed fit for human consumption following ante-mortem and post-mortem inspections.

Quarantine Systems: A closed-loop logistics system prevents cross-contamination with unverified biological materials during transport.

Note: Effective traceability requires the capability to track a finished batch of gelatin back to the specific slaughterhouse and date of processing, a standard fully integrated into Hengxin’s supply chain management.

Scientific literature confirms that the manufacturing process of gelatin significantly reduces potential infectivity. The transformation of collagen into gelatin involves severe chemical and thermal treatments that act as robust barriers against pathogens.

Current best practices, aligned with the European Pharmacopoeia (Ph. Eur.), involve specific processing parameters known to inactivate prion proteins:

Acid/Alkali Treatment: Prolonged exposure to extreme pH levels disrupts protein structures.

Thermal Sterilization: As practiced in state-of-the-art facilities, the extraction process often includes Ultra-High Temperature (UHT) sterilization (e.g., 138°C for a minimum of 4 seconds) or sustained heating at >133°C under pressure.

Filtration and Ion Exchange: Mechanical and chemical purification removes impurities at the molecular level.

This multi-barrier approach ensures that the resulting bone gelatin is chemically pure and biologically inert.

For global market access, adherence to international pharmacopoeia standards is non-negotiable. Shandong Hengxin Biotech Co., Ltd., as the largest manufacturer in Asia, aligns its quality management systems (QMS) with:

ISO 9001 & ISO 22000: For systemic quality and food safety management.

EDQM Guidelines: Demonstrating suitability for use in pharmaceutical products (TSE risk assessment).

Halal/Kosher Certification: Ensuring dietary law compliance which often overlaps with strict hygiene requirements.

The sourcing of bone gelatin demands a rigorous assessment of the manufacturer's technical capabilities and safety protocols. By integrating complete supply chain traceability with advanced processing technologies, manufacturers like Hengxin Biotech provide a secure foundation for the global food and pharmaceutical industries. For partners seeking uncompromised safety and consistency, reviewing the technical data sheets (TDS) and certification documents is the prudent next step.

[Learn more about our Bone Gelatin specifications and safety certifications]